What Is a Supply Chain?

A supply chain is the entire network of entities involved in the creation and delivery of a product or service. This network starts with the producers of materials or services and ends when they are refined into a finished product and distributed. Services provided after the sale, like returns or customer support, are often included in the supply chain.

A standard network of a supply chain includes:

- Raw material suppliers: Provide the basic resources needed to manufacture goods, such as metal, rubber, cotton, etc. They extract or harvest these materials.

- Manufacturers: Transform the raw materials into finished products by refining, processing, and combining various components. They manage the actual production process.

- Warehouses: Store and manage inventory at key points along the supply chain. They allow for the efficient reception and distribution of goods.

- Transportation providers: Move materials between the different links in the supply chain. This includes trucks, planes, ships, and railroads.

- Retailers and distributors: Purchase goods from manufacturers and sell them to consumers. This includes both brick-and-mortar stores and e-commerce channels.

An efficiently managed supply chain can reduce costs, increase profits, and promote sustainability. However, any disruption or inactivity in one part of the chain can ripple through the entire chain and halt it entirely.

Benefits and Risks of Supply Chains

Planning is a critical function in supply chain management. Companies must forecast demand and ensure they have adequate supplies to meet it. They also need contingency plans for potential disruptions or delays. Information sharing and collaboration between all entities in a supply chain are vital for alignment.

For example, the supply chain for a smartphone may start with mining companies that extract metals and other minerals. Component manufacturers then use these materials to produce screens, circuits, batteries, and plastic casings. Phone manufacturers assemble the parts into finished devices which are shipped to distribution centers. Retail outlets finally sell the phones to consumers.

An effective supply chain provides many benefits, including:

- Cost efficiency: Consists of the systematic elimination of excess waste and reduction of storage needs.

- Improved quality: Ensuring that all components meet the manufacturer’s specifications.

- Improved customer service: A well-managed supply chain ensures faster delivery times.

- Increased sales: Manufacturing processes can be easily scaled as demand grows.

- Competitive advantage: Efficient supply chains create efficiencies that rivals cannot match.

- Risk reduction: They minimize disruptions and delays.

However, supply chains also carry risks, such as:

- Single point of failure: One disrupted link can affect the whole chain.

- Inventory costs: High inventory levels increase working capital needs.

- Quality control: Defective parts and products can significantly affect the manufacturing process.

- Demand volatility: Sudden changes in customer demand levels can lead to unexpected inventory shortages.

- Shipping issues: Problems with international freight are a usual cause of delays.

- Supplier instability: A business’s over-dependence on a single supplier may result in instability.

The supply chain must be actively monitored and managed to maximize upside and minimize downside risks. Some best practices include:

- Streamlining processes to reduce waste.

- Using just-in-time (JIT) inventory systems.

- Establishing trusted, long-term supplier relationships.

- Implementing contingency plans for disruptions.

- Leveraging emerging technologies to improve visibility.

- Incorporating redundancy for critical distribution channels.

- Utilizing logistics partnerships for increased flexibility.

Supply Chain Examples

In today’s world, there are hundreds of thousands if not millions of supply chains that make up the modern world’s economy. Here are a few options from some of the world’s largest companies.

1. Tesla Automobiles

Tesla (TSLA) is a popular automobile brand that builds high-end electric vehicles (EVs) for customers. Tesla works with many third-party vendors who supply it with chips, batteries, chassis, engines, rubber tires, metal bodies, and many more. The company works with over 200 suppliers, including Emerson Electric and Garmin Ltd, which all have their place in the supply chain.

These components are assembled to create the final vehicle, which is shipped out to the end consumer.

2. Typical Coffee Supply Chain

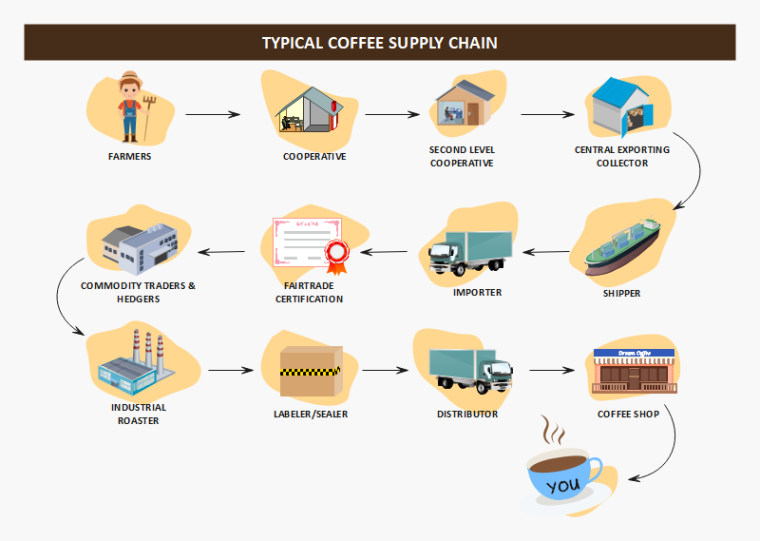

The diagram above is a great example of a relatively simple supply chain that produces coffee.

Everything begins with the farmers who grow coffee beans. The coffee beans produced by a large number of farmers are pooled together in farming cooperatives, which start the export process so that they can get their goods to the desired location.

The goods are shipped to the destination country where they are imported and certified. They are eventually sent to industrial roasters, where the coffee beans are finally made into a finished product. Finally, they are packaged and distributed to coffee shops, stores, or sometimes directly to consumers.

What Is Supply Chain Management?

Supply chain management (SCM) is the oversight of the flow of goods, services, finances, and information from the initial suppliers to the eventual end user. The goal of SCM is to maximize value for customers, stakeholders, and society while minimizing waste and costs. It involves coordinating and optimizing the entire production network.

At its core, SCM integrates supply and demand management functions. On the supply side, it encompasses sourcing raw materials, manufacturing and assembly, warehousing, and inventory tracking. On the demand side, it involves distribution, logistics, and order delivery. SCM aims to ensure the right goods are produced in the right quantities and distributed to the right locations at the right time in order to meet customer needs.

To achieve this, SCM relies on building relationships and collaboration between network partners. This includes suppliers, purchasing, production, logistics, marketing, and finance departments within a company. It also involves coordination with distributors, retailers, and customers externally. Information transparency and data sharing across the supply chain is crucial.

The key aspects of effective SCM include:

| Demand Forecasting | Predicting future demand to optimize inventory levels. |

| Sourcing and Procurement | Managing supplier relationships and purchasing. |

| Manufacturing Flow Management | Ensuring efficient production operations and processes. |

| Warehouse and Inventory Management | Storing and tracking stock efficiently. |

| Transportation and Logistics | Optimizing the shipment of goods. |

| Supply Chain Visibility | Monitoring assets and inventory in real-time. |

| Collaboration | Aligning plans and building partnerships across the chain. |

Successful SCM provides many benefits including reduced operating costs, improved customer service, increased sales, and higher profit margins. However, it requires significant integration and coordination between departments, business units, and partners. Supply chains can also be very complex and vulnerable to disruptions. SCM seeks to mitigate these risks.

With globalized operations and outsourcing, supply chains have grown to become exceptionally sophisticated webs. Advances in technology have enabled greater transparency and efficiency through automated processes and data analytics. The effective management of extended supply chains is now a source of competitive advantage for companies. Those with agile, flexible and resilient supply chain operations are better positioned to satisfy customer demands in a dynamic marketplace.

Supply Chain vs. Value Chain

A supply chain includes all the networks and components involved in producing and distributing a product or service for sale. A value chain begins in the idea creation phase and focuses on where the product’s value comes from to make it as valuable to customers as possible.

It involves the physical production of goods and value-driven activities such as production planning, marketing and sales strategies, design, innovation concepts, and more.